Dongguan Xitao Precision Ceramics Co.Ltd.

Contact:Mr. Tang

Phone:13790240258

Email:dgjdmj@126.com

URL:www.xtceramic.com

Address:Building B, No. C10, Xinxufeng Industrial Park, Lishi Industrial Zone, Changping Town, Dongguan City, Guangdong Province

Dongguan Xitao Precision Ceramics Co., Ltd.

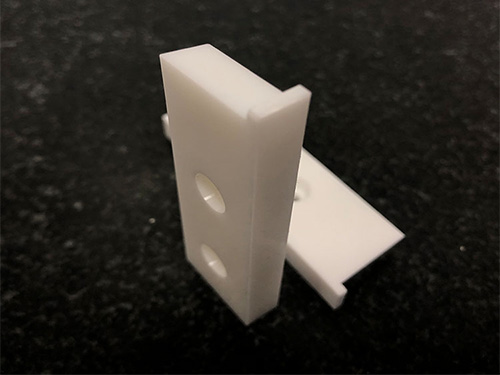

Focus on the production and sales of zirconia ceramics, alumina ceramics, ceramic punches and other products

National Service Hotline:

13790240258Dongguan Xitao Precision Ceramics Co.Ltd.

Contact:Mr. Tang

Phone:13790240258

Email:dgjdmj@126.com

URL:www.xtceramic.com

Address:Building B, No. C10, Xinxufeng Industrial Park, Lishi Industrial Zone, Changping Town, Dongguan City, Guangdong Province

Oxide ceramics are more and more widely used in the new energy industry due to their excellent acid and alkali corrosion resistance, high hardness and high wear resistance. The representative products are ceramic cutters for cutting aluminum foil film and tin foil paper. In addition, some wear parts in the new energy automation equipment line are also replaced with ceramics.

Dongguan Xitao Precision Ceramics Co., Ltd. is a high-tech enterprise integrating R & D, production and sales of industrial precision advanced ceramic products in the field of precision ceramics. We are committed to providing advanced ceramics with high strength, high toughness, wear resistance, corrosion resistance and high temperature resistance for domestic and foreign customers. The company has long-term cooperation with Japanese advanced ceramic manufacturers and domestic colleges and universities to jointly develop and produce advanced ceramics for new energy, machinery manufacturing, petrochemical, automotive, medical, semiconductor, SMT and other industries, to reduce costs for customers and improve production efficiency. Provide a full range of solutions.

The company has modern high-precision equipment to realize the independent completion of the entire production process of ceramic parts from the preparation of ceramic powder, green molding, sintering to the finishing of ceramic materials.

Our company has a ceramic R & D and manufacturing team composed of highly-educated and experienced industry experts. It constantly develops and improves new technologies and new processes, which provides guarantee for the company's continuous development.

Adhering to the business philosophy of customer first, our company is committed to providing quality services to customers around the world.

|

Sintering capacity |

|||||||||||

|

Maximum size / piece |

Zirconia |

Alumina |

|||||||||

|

Baton |

diameter |

Φ117 |

Φ139 |

||||||||

|

length |

150 |

180 |

|||||||||

|

tube |

Outer diameter |

Φ112 |

Φ117 |

||||||||

|

the inside diameter of |

Φ76 |

Φ80 |

|||||||||

|

length |

110 |

120 |

|||||||||

|

Dimensional accuracy of green billet |

|||||||||||

|

A. Cold isostatic pressing |

Zirconia |

Alumina |

|||||||||

|

Baton |

diameter |

Φ4.5→Φ115 |

Φ5→Φ139 |

||||||||

|

length |

110→200 |

130→230 |

|||||||||

|

tube |

Outer diameter |

Φ7.3→Φ115 |

Φ9.5→Φ140 |

||||||||

|

the inside diameter of |

Φ3→Φ70 |

Φ3.4→Φ80 |

|||||||||

|

length |

100→200 |

100→200 |

|||||||||

|

B. Dry press forming |

|

|

|||||||||

|

Sheet |

thickness |

3→25 |

4→28 |

||||||||

|

Length × width |

148*148 |

150*150 |

|||||||||

|

C. Injection molding |

|

|

|||||||||

|

Irregular pieces |

weight |

<100g |

|

||||||||

|

|

|

|

|

||||||||

|

The highest processing accuracy (mm) |

Product Size |

||||||||||

|

|

250*250*18 |

50*55*1 |

|||||||||

|

Flatness |

0.002 |

0.001 |

|||||||||

|

Parallelism |

0.005 |

0.001 |

|||||||||

|

Cylindricity |

0.003 |

||||||||||

|

Roundness |

0.001 |

||||||||||

|

Outer diameter accuracy |

0.002 |

||||||||||

|

Inner diameter accuracy |

0.005 |

||||||||||

|

Outline size |

±0.01 |

Step accuracy |

±0.002 |

||||||||

|

External / internal surface finish |

Ra<0.2μm |

||||||||||

Honing the highest processing accuracy

|

Maximum processing size |

Φ3→Φ80 |

|

Roundness |

0.002mm |

Copyright©www.xtceramic.com(copy Link)Dongguan Xitao Precision Ceramics Co., Ltd.

Dongguan Xitao Precision Ceramics Co., Ltd.Specializing in the production and sales of zirconia ceramics, alumina ceramics, ceramic punches, the company provides quality services, welcome to inquire:0769-82058382

Popular city promotion: Dongguan, Shenzhen, Guangzhou

Service Hotline

Follow WeChat